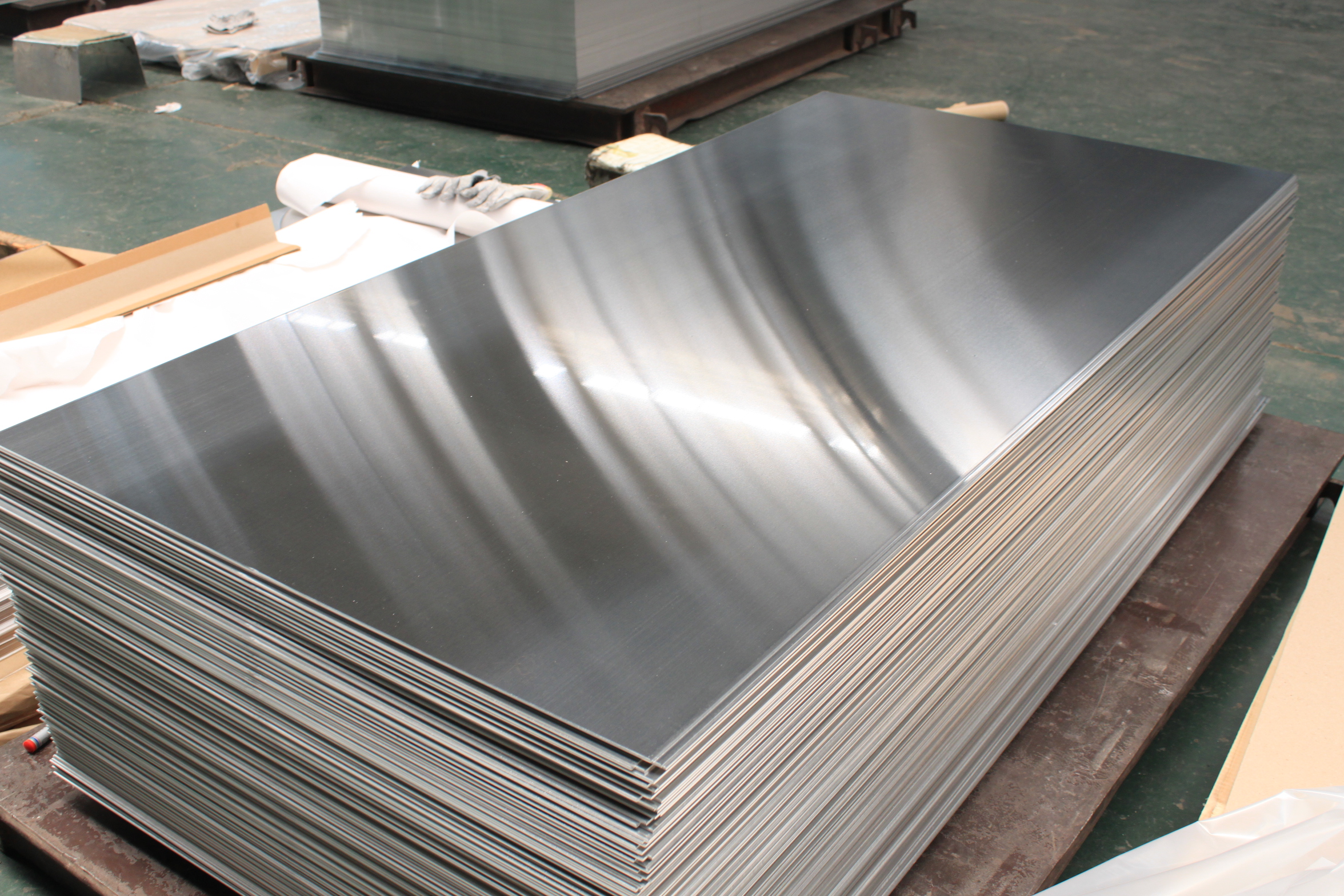

1100 Aluminium Plate:

Product Description

1100 aluminum for the industrial aluminum, aluminum content (mass fraction) of 99.00%, not heat treatment to strengthen. With high corrosion resistance, electrical conductivity and thermal conductivity, the density is small, good plasticity, through the pressure processing can produce all kinds of aluminum, but low strength. Other process performance is basically the same as 1050A. 1100 is usually used to require good forming processability, high corrosion resistance, does not require high-intensity not seen, such as video and chemical handling and storage equipment, sheet metal products, with spin extension of the processing of hollow hardware, welding key combinations , Reflectors, nameplates and so on.

Product Description

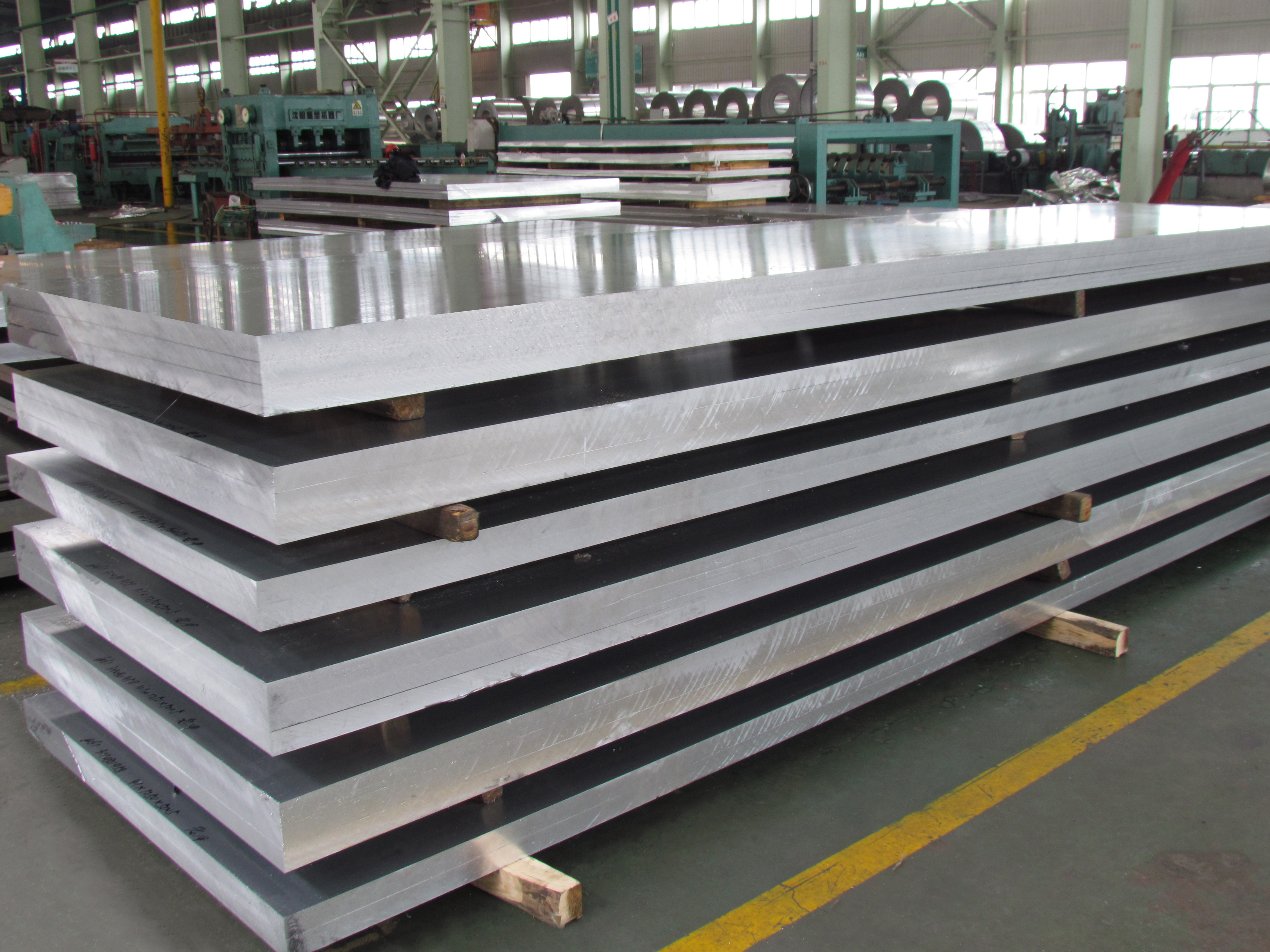

| Typical alloys | Material status | Thickness(mm) | Width(mm) | Length(mm) | Typical products | From Quantities | Application |

| 1100 aluminum plate |

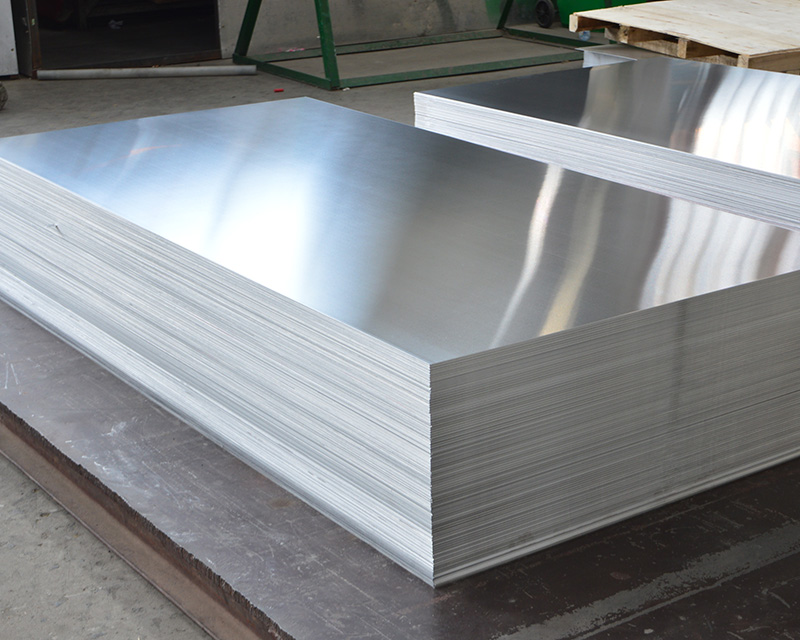

O,H12,H14,H16 H18,H19,H22,H24 H26,H28,H32,H34 H36,H38 |

0.2-4.5 | 300-1600 | 800-6000 | Cooking utensils, building materials, heat exchangers | 3 tons | Heat sinks, caps, printing plates, cookware, building materials, heat exchanger components |

Preformance

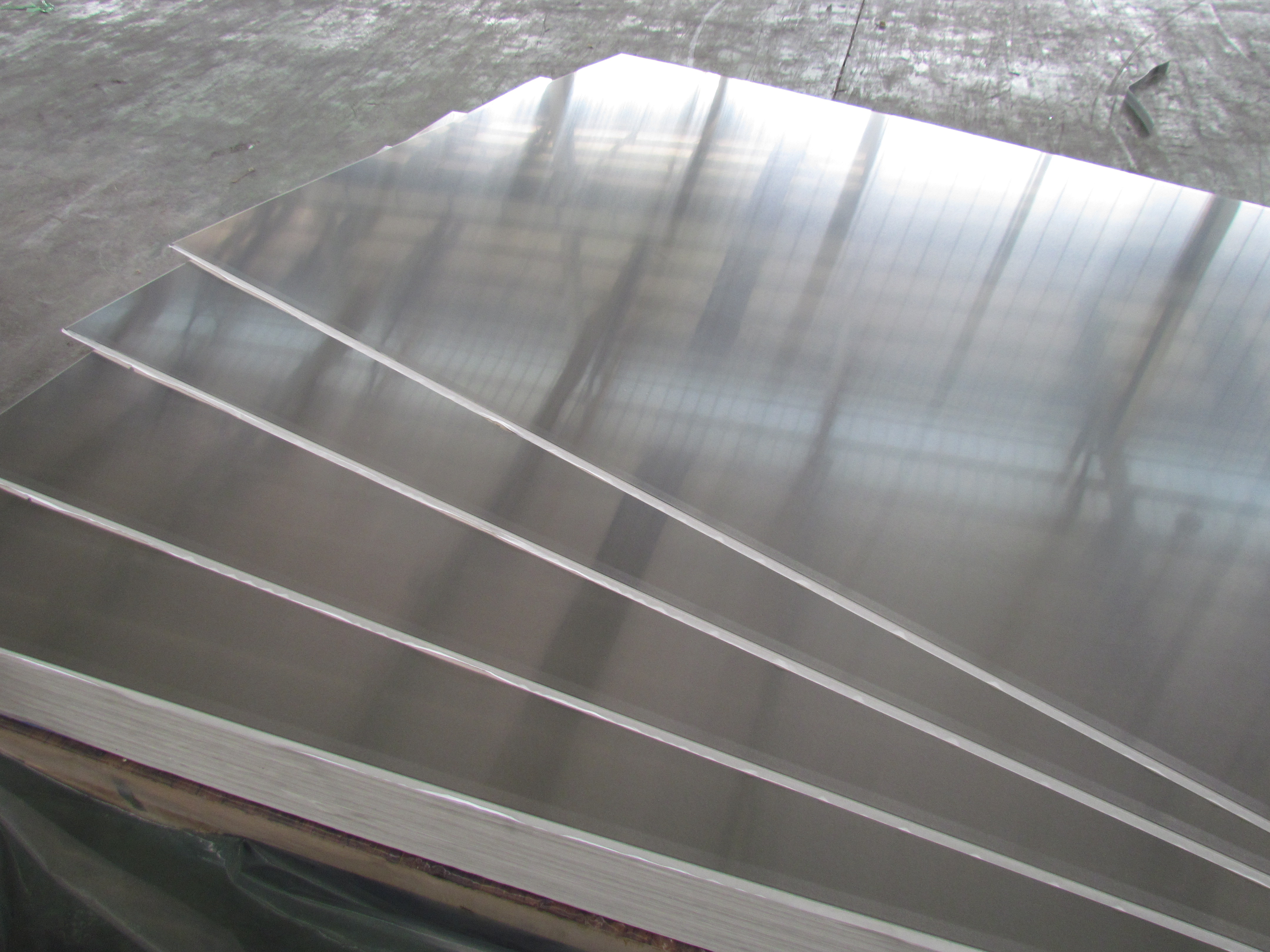

1, Has excellent forming processing characteristics, high corrosion resistance, electrical conductivity and thermal conductivity;

2, Long life, lower cost, but also has a high recovery value;

3,1050 Aluminum processing technology is mature, the price relative to other high-grade aluminum alloy has a huge advantage;"